Profile wire

By standard EN ISO 16120-2.

Production range according to the attached specifications.

Technical specification

| Steel | Chemical composition | ||||

|---|---|---|---|---|---|

| EN ISO 16120-2 | % C | % Mn | % P max. | % S max. | % Si max. |

| C4D | ≤ 0,06 | 0,30 – 0,60 | 0,035 | 0,035 | 0,30 |

| C7D | 0,05 – 0,09 | 0,30 – 0,60 | 0,035 | 0,035 | 0,30 |

| C9D | ≤ 0,10 | 0,30 – 0,60 | 0,035 | 0,035 | 0,30 |

| C10D | 0,08 – 0,13 | 0,30 – 0,60 | 0,035 | 0,035 | 0,30 |

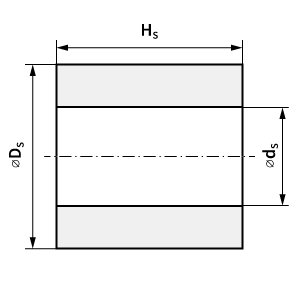

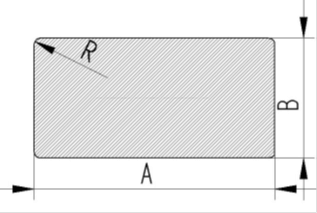

Nominal dimensions and tolerances of dimension can be selected within the range specified intervals and aspect ratio.

| Dimension a [mm] | Dimension b [mm] | Tensile strength [MPa] | Note | R max. [mm] |

|---|---|---|---|---|

| 5,0–8,0 | 3,5–5,6 | min. 500 | b/a ≥ 0,7 | 1,5 |

| Dimension a [mm] | Dimension b [mm] | Tensile strength [MPa] | Note | R max. [mm] |

|---|---|---|---|---|

| 5,0–12,0 +/-0,10 | 5,0–12,0 +/-0,10 | 550–950 (annealed max. 450) | a/b ≤ 2,0 | 0,12 x A |

| Dimension a [mm] | Dimension b [mm] | Tensile strength [MPa] | Note | R max. [mm] |

|---|---|---|---|---|

| 5,0–12,0 +/-0,10 | 5,0–12,0 +/-0,10 | 550–950 (annealed max. 450) | a/b ≤ 2,0 | max. 4,0 |

More detailed information on the products can be provided by

- Jan Hamrozi

- T +420 596 090 347

- +420 775 877 316

- E jan.hamrozi@zdb.cz